Lava 15 High Traffic Coating

Reinforced Coating Membrane for High Traffic Concrete

Lava 15’s polyurethane membrane system for high traffic concrete areas delivers an incredibly resilient weatherproof barrier for a wide range of pedestrian and vehicle-based surfaces. Incorporate industrial-grade shielding for walkways, bridge decks, stadium stands, parking garages, and much more. The system’s flexible, waterproof membrane provides the rapid curing, superior tear strength, and extreme weather performance necessary to withstand daily impact in high traffic areas.

Proven Performance

With 25 years of reliability and 1.3 billion square feet applied without failure, Lava 15 debuts in the USA with confidence and proven success.

Fast & Easy to Apply

Seamlessly applies, offering reduced leaks, superior insulation, and versatile adaptability, with fast drying and durability within 30 min.

High Elasticity

Lava 15 acts as a formless, jointless barrier, allowing owners to protect assets year-round from the wear and tear of foot and vehicle deck traffic.

Installation Instructions:

This step-by-step process ensures a seamless integration of our polyurethane

High Traffic Concrete

Installation instructions for High Traffic Concrete Substrates

For newly set concrete structures, at least 28 days curing time is required before applying Lava 15. Both new and existing concrete surfaces must be completely dry prior to application. Oil, grease, curing compounds, loose particles, moss, algae growth, laitance, friable matter, dirt, bituminous products, and previous water proofing materials must be removed.

Application Tools & Materials Required

System can be spread out on concrete surfaces using a roller, brush, squeegee, or airless spray. The use of polyester fabric matting for reinforcement is optional.

For new surfaces, ensure that concrete has undergone at least 28 days of curing time.

I. Initial Roof Surface Inspection

Prior to applying the Lava 15 coating system, any residual repairs should be performed. It is important to inspect and examine all elements of the concrete surface, including but not limited to:

- Wet areas or areas with sitting water must be cut out and replaced before application

- Drainage performance

- Water leaks

- Miscellaneous penetrations

- Existing corrosion or rust areas

- HVAC flashing and/or debris

- Seams, terminations, and reglets

- Coping and flashing

- Sleepers and pitch pockets

- Sign or display anchorage

- Miscellaneous anchored devices, equipment, or structural supports

II. Roof Surface Preparation

For optimal results, careful surface preparation is important. The surface should be free of any pollution that could compromise the membrane’s adhesion. .

A. For best results, the surface should be washed clean, free of loose materials, stains, grease, dust, debris, and other contaminants.

B. System can be spread out on concrete surfaces using a roller, brush, squeegee, or airless spray. The use of polyester fabric matting for reinforcement is optional.

C. Optimum moisture shouldn’t be higher than 8%. Do not use Lava 15 system on wet surfaces.

D. Compressive strength of substrate should be at least 25 MPa and viscous strength properties should be at least 1.5 MPa.

E. A grinding machine can be used to remove dust, filth, fats, oils, organic materials, and old loose coatings from existing concrete.

F. Smooth off any surface imperfections found along membrane coverage area.

G. Cracks, joints, and/or voids throughout surface should be filled with Lava PU Mastic.

H. Utilize polyester tape or geotextile for flashing drains, joints, and base angles.

I. Ensure that all adjoining surface areas that are not to receive the Lava 15 membrane be thoroughly masked and protected.

J. Setup a suitable, easy-to-access workstation for the sorting and mixing of all membrane materials.

K. Schedule and synchronize applications of each Lava 15 layer for accurate coating times. Make sure to apply the entire system during temperature conditions between 41 °F and 95 °F.

Step 1: Wash and Clean Surface Before Lava 15 Application

Surface Washing: Remove Debris & Prepare for Lava 15 CoatingWash

Wash entire surface clean, removing all surface debris, dirt, embedded stains, chemicals or oils, and organic matter.

Step 2

Inspect

Inspect and verify that the entire roof surface is completely dry and free of wet spotting.

Step 3

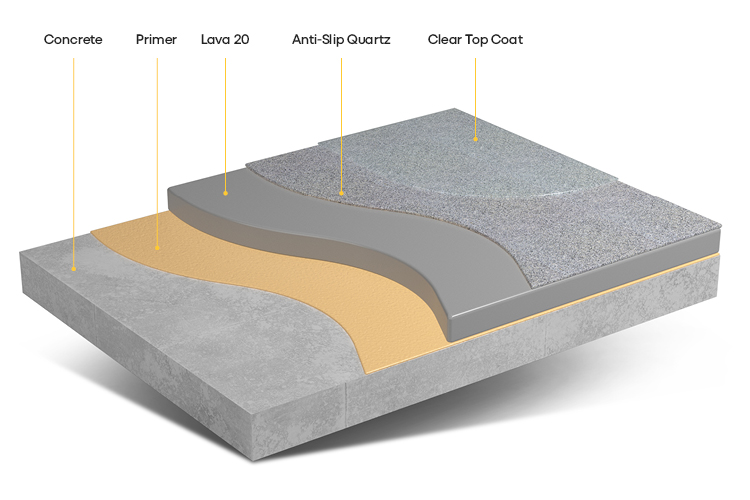

Primer

Prime the entire surface area with Lava 15 Quick Primer at a rate of one gallon per 300-350 sq. ft. and allow for a minimum of 15-30 minutes dry time. Concrete or cement screed are highly absorbent surfaces and require cure times according to manufacturer specifications.

Step 4

Membrane

a. Cracks, joints, and/or voids throughout roof surface should be filled with Lava PU Mastic.

b. Wall-to-floor connections, joints, 90° angles, chimneys, pipelines, waterspouts (siphon), etc. should always be reinforced with geotextile matting or equivalent, overlapping strips by 5-10 cm in order to strengthen the entire surface.

• Use Lava 20 Vertical Membrane for vertical and sloped surfaces, specifically formulated with high viscosity for easy application on parapet walls and other vertical roof structures.

• Use Lava 20 Detail Membrane for patching or filling large holes, gaps, and other roof penetrations, specifically formulated for rapid, bubble free curing over roof detail structures.

c. A cut piece of fabric can be applied over still-wet Lava 15, then pushed inward until fully absorbed. Once fully absorbed, saturate this area again with additional Lava 15.

d. Coat the entire surface area with Lava 15 Waterproofing Membrane at a rate of 18.4 sq. ft. per gallon.

e. By incorporating Lava 15 Catalyst, the entire surface can be covered in a single coat. Thoroughly mix 0.19 gallons ofLava 15 Catalyst directly into a 6.6-gallon bucket of membrane.

Step 5

Topcoat Anti-Slip

Apply theLava 15 Top Coat evenly across the entire area at a rate of 1 gallon per 215 sq ft. When using a colored Top Coat, along with Quartz or Aggregate for an Anti-Slip Finish, the consumption rate is typically halved due to the textured granular surface, requiring approximately 1 gallon per 100 sq ft, depending on the size of the aggregate quartz.

a. For final color stable, chalk-free surface appearances, apply no more than 1 or 2 layers of Lava 15 Top Coat.

b. For final dark colors, additional custom colors can be ordered.

Step 6

Curing & Finishing

Do not apply any Lava 15 layers thicker than 2.5 mm (dry film). For ideal curing, the temperature range during/after application should be between 41 °F and 95 °F. If the temperature conditions are too high, curing is hastened. If the temperature conditions are too low, curing is delayed.

Lava 15 Poly Membrane Technical Data

PROPERTY | RESULTS | TEST METHOD |

Elongation at Break | < 600 % | ASTM D 412 / DIN 52455 |

Tensile Strength | > 4 NI mm2 | ASTM D 412 / DIN 52455 |

Water Vapor Permeability | > 25 gr/m2/day | ISO 99932:91 |

Resistance to Mechanical Damage by Static Impression | High Resistance (class: P3) | EOTA TR-007 |

Resistance to Mechanical Damage by Dynamic Impression | High Resistance (class: P3) | EOTA TR-006 |

Resistance to Water Pressure | No Leak (1m water column, 24h) | DIN EN 1928 |

Adhesion to concrete | >2.0 N/mm2 (concrete surface failure) | ASTM D 903 |

Crack Bridaina Capability | Up to 2 mm crack | EOTA TR-008 |

Hardness (Shore A Scale) | 65-70 | ASTM D 903 |

Resistance to Root Penetration | Resistant | UNE 53420 |

Solar Reflectance (SR) | 0.87 | ASTM E903-96 |

Solar Emittance (e) | 0.89 | ASTM E408-71 |

Thermal Resistance (176 °F for 100 days) | Passed. No significant changes | EOTA TR-011 |

UV Accelerate – Aging in the Presence of Moisture | Passed. No significant changes | EOTA TR-010 |

Resistance After Water Aging | Passed | EOTA TR-012 |

Hydrolysis (5% KOH, ? days cycle) | No significant elastomeric channel | Inhouse Lab |

Construction Material Fire Class | B2 | DIN 4102-1 |

Resistance to Flying Sparks and Radiation Heat | Passed | DIN 4102-7 |

Service Temperature | -22 °F to +302 °F | Inhouse Lab |

Shock Temperature (20 min) | 392 °F | Inhouse Lab |

Rain Stability Time | 3-4 hours | Conditions: 68 °F, 50% RH |

Light Pedestrian Traffic Time | 18-24 hours | Conditions: 68 °F, 50% RH |

Final Curing Time | 7 days | Conditions: 68 °F, 50% RH |

Chemical Properties | Good resistance against acidic and alkali solutions (5%), detergents, seawater, and oils. | |

High Traffic Concrete Application Term Rates

| Coverage Term | Primer (Gal/Sq) | DFT mils | Geotextile (6 mils) | Lava 15 Gal/Sq | DFT Mils | Catalyst compatible | Topcoat Gal/Sq | DFT mils | Total DFT mils | Warranty |

| 15 years | 0.47 | 2 | N | 3.6 | 55 | Y | 0.88 | 8 | 65 | Platinum |

* DFT (Dry Film Thickness) is rounded to nearest mil, and is theoretical. Actual DFT will vary dependent on substrate profile, application technique and waste factor.